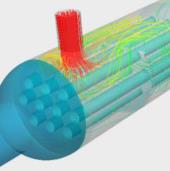

Chemical reaction engineering (CFD) Computational Fluid Dynamics module analysis

hVI provides chemical reaction engineering (CFD) module analysis, which is specifically used for the analogy of chemical engineering systems. It can effectively analyze the changes in chemical composition, reaction kinetics, fluid flow and temperature with space and time.

The applications of chemical reaction engineering module analysis, such as chemical reactors and reaction systems, are used to analyze quality transfer-based systems, including reactor units, separation and mixing processes, chromatography and electrophoresis. This analysis provides an effective understanding of chemical engineering, chemical reaction engineering, electrochemical engineering, biotechnology, and transfer phenomena.

hVI makes assumptions based on the customer's real field, building these descriptions in one, two or three dimensions, and considering temporal correlation.

Comparisons of simulation and experimental results, such as those obtained by the reactor or the system itself, can also be their prototype test results. Models for mass transfer, heat transfer and fluid flow, often involve common material parameters. The sources of information are from literature or similar systems, which must be iteratively corrected to improve the correctness of the model analysis.

After the hVI completes the optimization model, the model can be used to apply the chemical reactor or process to the customer under various operating conditions in the real field. From the validation of the final model and the precise results, it can be used directly for more precise R&D or chemical reactor optimization, as well as for future system control.